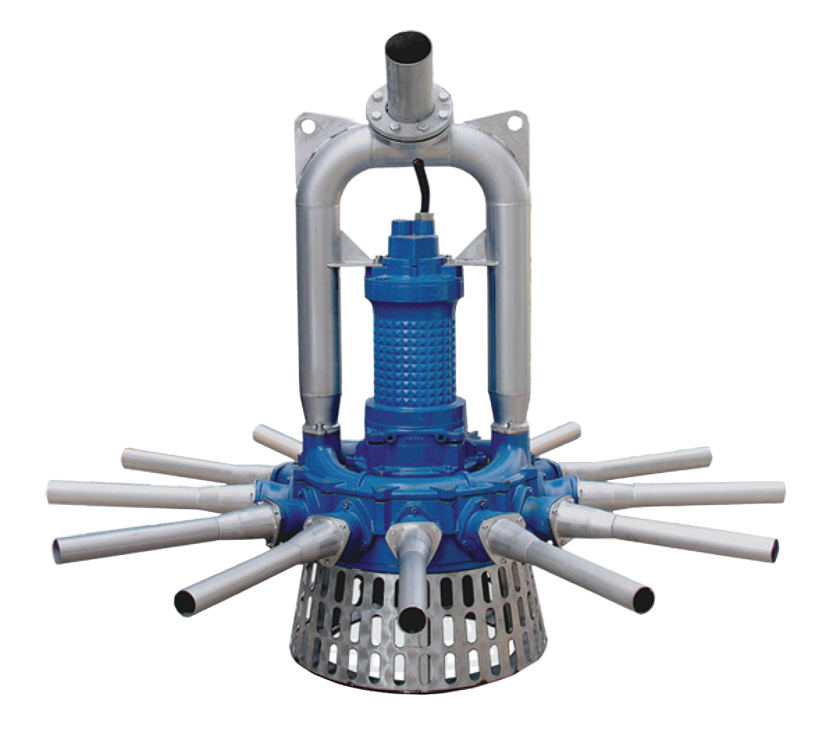

The pressure system called OSSI-MIX (OM) is designed to provide a very long service life, all wearing parts can be easily replaced from the edge of the tank using simple tools. The impeller has an exclusive fine adjustment control system.

The operation of the OM system is based on the use of an electric submersible pump equipped with a special hydraulic system with a DUPLEX stainless steel 3-channel centrifugal impeller operating in a special 12-outlet diffuser and an AISI 304 stainless steel air supply system, which is passed through a external blower is pressurized. In the mixing chambers the sludge comes into contact with air supplied by a blower, the air-sludge contact takes place in a very turbulent ring-shaped pipe made of AISI 304 stainless steel.

The high hydraulic efficiency of the impeller ensures that large amounts of wastewater are mixed with air with relatively little power. The pump flow is divided over the five or twelve nozzles that bring the sludge to be aerated to the same number of mixing chambers. The compact and solid construction with dry motor and oil chamber positioned between the hydraulic part and the electric motor, sits at the bottom of its stainless steel tripod stand and can also be installed very easily when the tank is full.