The gearbox is a standard wormwheel reduction system with all bearings supported within a fully lubricated gearbox. The mechanism for variation of the stroke length a positive stroke spring return that is operated by an eccentric.

PUMPING HEADS

Pumping heads are made in standard executions: S.S. 316 or PVC

A wide range of other materials like HASTELLOY, ALLOY, PTFE, PVDF, PP are according to the liquid to be dosed. Piston gaskets are of the lip type design and are available in a wide range of materials (FPM, EPDM, SILICONE, ADIPRENE) and also in PTFE packing. Jacketed pump head for either cooling or heating are available to suit requirements. Piston glandling arrangements can be supplied with water washed seals to continuously flush the piston.

PLUNGERS

There are made in S.S. 316 or Ceramics.

STROKE ADJUSTMENT

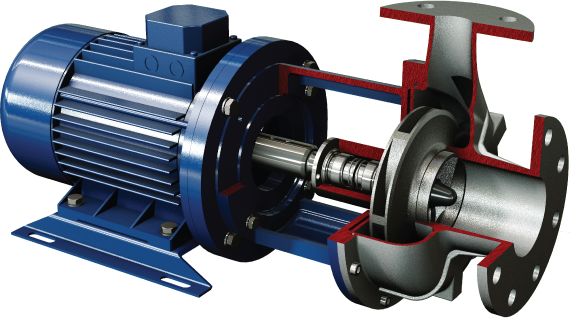

Flow rate adjustment is possible while running or at standstill. The movement of the piston is based on a precise reciprocating gearbox, which provides an exact volumetric displacement.

Stroke adjustment can be carried out:

- Manual: by a linear micrometer screw

- Electrical: via servo motor with 4-20 mA signal upon request interface PROFIBUS or other BUS

- Pneumatic: by a pneumatic servo control with signal from 3 to 15 PSI

SUCTION AND DISCHARGE CONNECTIONS

Normally are threaded, but they can be supplied also flanged. All the pumps have a ball valve standard: single and double balls by the function of the piston diameter or the material execution.

MULTIPLE HEADED PUMPS

Different multiple heads units are available on request.

Each pumping element has independent adjustment while running or at standstill.

HIGH PRESSURE EXECUTION

These pumps use the same crank mechanism of the pumps A type, but the difference is on the hydraulic part that must be suitable to satisty very hard requirements.